Water repellent chemicals transform textiles, making them water resistant while breathable and comfortable.

This guide covers their role in the textile industry, from fluorocarbons and silicones to outdoor apparel and technical fabrics. We’ll also look into environmental concerns and sustainable alternatives, with Colourinn Auxiliaries offering innovative water repellent chemicals textile solutions.

Join us to discover how these chemicals improve fabric durability and performance while meeting modern sustainability demands.

What Are Water Repellent Chemicals?

Water repellent chemicals are special substances applied to textiles to prevent water absorption. By reducing the fabric’s surface energy, they cause water to bead up and roll off instead of soaking in.

These chemicals are essential in creating fabrics that can withstand rain, stains and moisture while remaining breathable. In the textile industry, water repellent chemicals textile applications ranging from outdoor gear to medical textiles, ensuring functionality without compromising comfort.

How They Work

The science behind water repellent chemicals is hydrophobicity. These chemicals coat fabric fibres, creating a low-energy surface that repels water. Unlike waterproof coatings that block air and vapour, water-repellent finishes allow breathability, making them perfect for apparel. Common mechanisms include:

- Surface Tension Reduction: Changes the fabric’s surface to resist water penetration.

- Contact Angle Increase: Ensures water forms droplets with a high contact angle (>90°), indicating repellency.

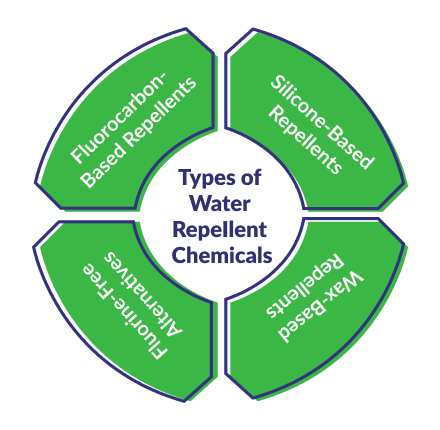

Types of Water Repellent Chemicals

The different water repellent chemicals found in textiles have different properties and applications. Understanding differences helps manufacturers select the right solution for their needs.

Fluorocarbon-Based Repellents

Fluorocarbons (C6 and C8 chemistries) are highly effective at repelling water and oil. They form a low-energy film on fabrics for outdoor wear and technical textiles,. Nevertheless, concerns about the PFOA and PFOS long-chain alternatives have moved to shorter chains.

Silicone-Based Repellents

Silicone finishes have good water repellency and flexibility while maintaining fabric softness. They are eco-friendly than fluorocarbons and are used for water repellent chemicals in textiles for cotton and synthetic blends. They are thermostable and UV-resistant for outdoor use.

Wax-Based Repellents

Wax-based finishes, one of the oldest methods, provide affordable water repellency but lack durability, often washing out over time. Suitable for less demanding applications such as casual wear.

Fluorine-Free Alternatives

Emerging fluorine-free options, like nanoparticle coatings and bio-based waxes (e.g. beeswax, chitosan), offer sustainable water repellent chemicals with reduced environmental impact. These are gaining popularity in eco-conscious markets.

| Type | Pros | Cons | Applications |

| Fluorocarbon | High water/oil repellency, durable | Environmental concerns | Outdoor gear, workwear |

| Silicone | Eco-friendly, soft handle | Limited oil repellency | Apparel, home textiles |

| Wax | Cost-effective | Less durable | Casual wear |

| Fluorine-Free | Sustainable | May require frequent reapplication | Eco-friendly textiles |

Explore innovative textile finishing chemical solutions designed to improve fabric texture, durability, and appearance for modern applications.

Applications in the Textile Industry

Water repellent chemicals are used in various industries to enhance functionality and durability. Key applications are:

- Outdoor Apparel: Jackets, hiking gear & raincoats need water repellency for weather protection.

- Workwear: Clothing for construction and utility workers uses these chemicals to withstand harsh conditions.

- Sportswear: Athletes benefit from moisture-resistant fabrics that keep them dry during activities.

- Technical Textiles: Tents, awnings and medical textiles use water repellent chemicals for durability and hygiene.

Environmental Considerations

Water repellent chemicals improve textile performance but are increasingly environmentally harmful. C8 chemistries are associated with bioaccumulation and toxicity and are banned in many regions. The industry is responding with sustainable alternatives:

- Fluorine-Free Finishes: Silicone and bio-based coatings reduce environmental harm.

- C6 Chemistry: Less bio-accumulative than C8, though still less effective.

- Regulatory Compliance: Safer practices include programs like the Zero Discharge of Hazardous Chemicals (ZDHC).

So manufacturers need to compromise performance for sustainability and look to eco-friendly water repellent chemicals and textile solutions to meet consumer and regulatory demands.

How to Apply Water Repellent Chemicals

Applying water repellent chemicals requires precision for uniform results. Common methods are:

- Padding: Fabrics are dipped in a chemical bath and pressed to remove excess liquid for an even application.

- Spraying: Good for targeted applications, but less uniform than padding.

- Foam Processing: Uses minimal water, hence eco-friendly.

Fabrics must be clean and free of residues (e.g. surfactants, oils) to avoid impairing repellency. The ph of 4-5 during application enhances effectiveness.

Maintaining Water Repellent Properties

The effectiveness of water repellent chemicals can diminish due to wear, dirt or laundry. To maintain performance:

- Clean fabrics with mild detergents to remove contaminants.

- Reapply treatments using spray or wash-in products.

- Follow care instructions as some finishes are sensitive to dry cleaning.

Future Trends in Water Repellent Chemicals

The future of water repellent chemicals textile solutions lies in innovation and sustainability. Emerging trends are:

- Nanotechnology: Super-hydrophobic coatings inspired by lotus leaves for better repellency.

- Self-Cleaning Fabrics: Treated with photocatalytic coatings to repel dirt and stains.

- Bio-Based Solutions: Natural materials like cellulose and chitosan for eco-friendly options.

These will give better durability and reduced environmental impact as per the global sustainability goals.

Why Colourinn is the Best in Water Repellent Solutions

At Colourinn Auxiliaries we understand the magic of water repellent chemicals in textiles. This guide has covered types, applications and sustainable innovations of water repellent chemicals and how important they are in creating durable and functional fabrics. Our commitment to quality ensures our water repellent chemicals textile solutions meet industry standards from outdoor apparel to technical textiles.

Ready to get your textiles eco-friendly and high-performance water repellent solutions? Contact Colourinn Auxiliaries to know more about our products and get a clear picture of how we can help you in your textile production with sustainable and reliable finishes. Let’s create fabrics that can withstand the elements together!

Frequently Asked Question(FAQs)

Q1. What are water repellent chemicals used for in the textile industry?

A. Water repellent chemicals are used in the textile industry to create fabrics that resist moisture, keeping garments dry and enhancing their durability.

Q2. Are water repellent chemicals safe for clothing and the environment?

A. Modern water repellent chemicals are designed to be both fabric-safe and environmentally friendly, with many manufacturers moving into non-fluorinated, sustainable options.

Q3. Can water repellent chemicals be applied to all types of textiles?

A. Yes, water repellent chemicals can be applied to a wide range of textiles including cotton, polyester, nylon, and blended fabrics, depending on the formula.