Printing

- Home

- /

- TEXTILE & DYES ...

- /

- Printing

Colourinn Auxiliary is one of the largest Textile Finishing Chemicals Manufacturer and supplier in India & Bangladesh

We all understand what finishing means. Textile finishing is all about improving the final look of the fabric. It enhances the appearance, feel, and performance of the product. After textile dyeing comes the finishing step which makes the fabric ready to use. The finishing process improves the aesthetics of the fabric.

Textile finishing is done to achieve the desired appearance after the cloth is manufactured. Not only it enhances the aesthetics of the textiles, but also improves the functionality of the product. The textile finishing manufacturers focus on creating auxiliaries that help in achieving the desired results.

Colourinn is one of the most reputed global textile finishing manufacturers. We bring a variety of textile finishing agents which make the fabric softer and more appealing. Reaching the desired shade is not as easy as it seems no matter how good a dye you use. But, colour deepening agents make it possible for you to achieve the darkest of blacks and that too with minimal efforts.

Other finishing agents include chlorine fastness improver which helps in keeping the shade intact even in hard chlorinated water so that your cotton clothes don’t fade within a few days.

Keeping the fabric in good condition is also a challenge. The fabric can get dirty and look unattractive while going through the process of cutting and getting into the final shape. Finishing agents like oil, water and stain repellents make it easy for you to keep the beauty of the fabric intact during the processing stage.

Some fabrics need to be flame safe and there are finishing agents that help in achieving this effect. Moreover, some fabrics such as cotton and rayon wrinkle more than others. A wrinkle resistant agent can make the fabric easy to keep. Even fragrance care agents are available to prevent the unbearable smell that sometimes generates while the dyeing process.

As a textile finishing agent manufacturer, our manufacturing unit produces all varieties of finishing agents. To make the finishing process pleasing and outcomes appealing, we bring you every possible finishing agent so that the fabric looks great in the end. The finishing agents are applied before the fabric is cut or sewn into the final outfit so that the next procedure becomes easier.

As finishing agents add softness and improve the performance of the fabric, not only it helps in judging the quality of the fabric, but also makes the stitching process easier. We are among the top textile finishing agent manufacturers in the world. You can browse our finishing agent products here.

You can explore the varieties here.

How pre-treatment changes the textile?

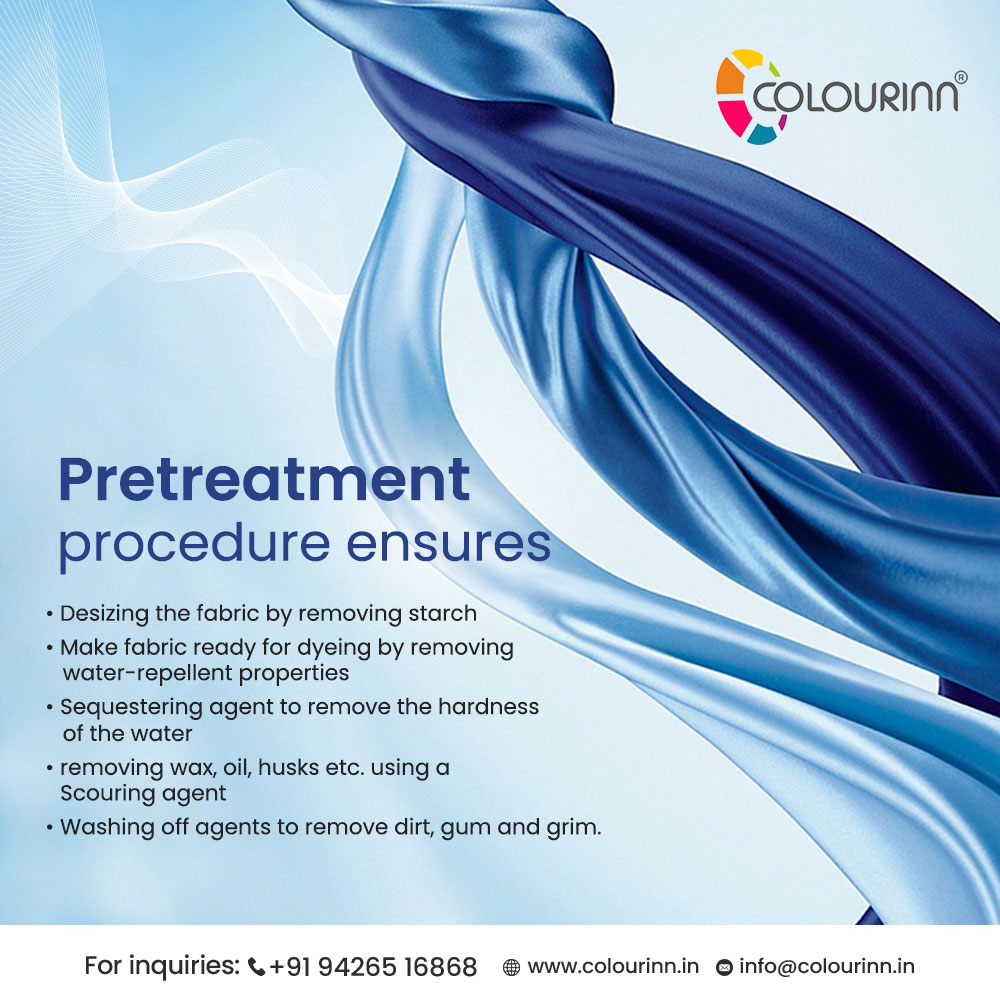

Pre-treatment of textiles involves a series of processes before dyeing, printing, or finishing. These

treatments bring about several changes in the fabric. Firstly, pre-treatment cleans the fabric,

removing dirt, oils, and contaminants to create a clean surface. It also desizes the fabric, removing

the starch or sizing agents used in weaving. Scouring eliminates natural impurities, enhancing

absorbency for better dye penetration. Bleaching lightens the fabric's color or removes stains.

Mercerization improves strength, luster, and dye affinity in cotton fabric. Singeing removes

protruding fibers, creating a smoother surface. Anti-pilling treatments minimize the formation of

pills on the fabric. Overall, pre-treatment enhances the fabric's appearance, absorbency, dye

penetration, color fastness, strength, and quality, making it ready for subsequent processing stages.

Why Choose Eco-Friendly Pre-Treatment Chemicals from Colourinn Auxiliary

By choosing Colourinn Auxiliary's eco-friendly pre-treatment chemicals, you make a conscious choice

towards sustainability and environmental responsibility. Our commitment to innovation, quality, and

the planet ensures that you receive products that are not only effective but also eco-friendly. Join us

in our journey towards a greener textile industry. Choose Colourinn Auxiliary's eco-friendly pre-

treatment chemicals today and make a positive impact on the environment while achieving

exceptional results.

Textile Pre-treatment FAQs

Colourinn is the best Textile chemical manufacturer and supplier in India with more than 40 years of

experience.

Pre-treatment is necessary to clean the fabric, remove impurities, enhance absorbency, improve

dye penetration, and ensure uniformity. It also prepares the fabric for better color fastness,

strength, and overall quality.

Pre-treatment can alter fabric properties significantly. It improves absorbency, dye penetration,

and color fastness. It also enhances strength, luster, and appearance while minimizing pilling. Pre-

treatment creates a suitable base for dyeing, printing, and finishing processes.

Pre-treatment processes can be optimized to reduce water and energy consumption, as well as

minimize the use of harmful chemicals. Eco-friendly pre-treatment methods contribute to

sustainable textile production and reduce environmental impact.

Yes, pre-treatment methods may vary based on the fabric composition. For example, cotton

fabrics may undergo mercerization, while synthetic fibers may require different treatments to

achieve desired results.