The textile industry is constantly evolving, and advances in technology have led to significant improvements in the production process. Textile auxiliaries are one field of the industry that has witnessed substantial advancements.

Textile auxiliaries are chemical compounds that are used to enhance the properties of textiles such as color, durability, and functionality. With the growing demand for textiles that are sustainable, functional, and aesthetically pleasing, the use of advanced textile auxiliaries is becoming increasingly important.

This article will explore the future of textile auxiliaries and the advancements in nanotechnology, smart textiles, and sustainable materials that are revolutionizing the textile industry. By integrating these advanced technologies into textile auxiliaries, the industry can create textiles that are not only functional and durable but also environmentally friendly and sustainable.

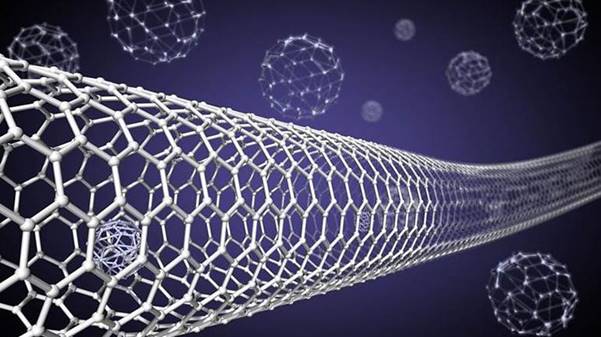

Nanotechnology in Textile Auxiliaries

Nanotechnology refers to the manipulation of matter on an atomic and molecular scale. In the textile industry, nanotechnology has enabled the development of advanced textile auxiliaries that enhance the properties of textiles. Nanoparticles can be added to textile auxiliaries to improve various characteristics such as water repellency, stain resistance, and UV protection.

Nanotechnology has revolutionized the textile industry in several ways.

- Enhanced durability: Nanotechnology has enabled the development of textiles that are more durable and resistant to wear and tear. Nanoparticles can be added to textile auxiliaries to create fabrics that are stronger and more resilient than traditional textiles.

- Improved functionality: Nanotechnology has made it possible to create textiles that have enhanced functionality. For example, textiles treated with nanotechnology can have water-repellent, stain-resistant, and UV-protective properties.

- Environmental sustainability: Traditional textile auxiliaries contain harmful chemicals that are hazardous to the environment. By using nanotechnology, textile manufacturers can develop auxiliaries that are biodegradable and non-toxic, making them safer for workers and the environment.

- Self-cleaning fabrics: Nanotechnology has enabled the development of self-cleaning fabrics. Textiles treated with nanotechnology can have a self-cleaning effect that reduces the need for frequent washing and prolongs the lifespan of the textile.

- Lightweight and breathable fabrics: Nanotechnology has made it possible to create lightweight and breathable fabrics that are more comfortable to wear. By employing nanoparticles, it is possible to manufacture fabrics that possess greater porosity and improved moisture-wicking characteristics.

These advancements have opened up new possibilities for textile manufacturers and designers, leading to the creation of textiles that are more versatile, comfortable, and sustainable.

Smart Textiles in the Textile Industry

Smart textiles are fabrics that have been engineered to have additional functionalities beyond their basic textile properties. They are designed to interact with their environment, either by sensing and reacting to changes in the environment or by actively changing the environment themselves. Smart textiles use technology such as sensors, actuators, and control systems to achieve their advanced functionality.

Smart textiles have a wide range of potential applications in industries such as healthcare, sports, fashion, and automotive. Here are some examples of smart textiles:

- Wearable technology: Smart textiles can be used to create wearable technology that monitors vital signs, activity levels, and other health-related data.

- Climate-controlled clothing: Smart textiles can be designed to regulate temperature and humidity levels, making them suitable for use in extreme weather conditions.

- Injury prevention: Smart textiles can be used to prevent injuries by providing additional support to the body during physical activities.

- Fashion: Smart textiles can be used in the fashion industry to create garments that change color or texture in response to environmental factors or user input.

- Automotive: Smart textiles can be used in the automotive industry to create interior fabrics that regulate temperature, monitor driver fatigue, and provide additional safety features.

Smart textiles are an exciting area of development in the textile industry. They have the potential to transform the way we interact with our clothing and the environment around us. As technology continues to advance, we can expect to see even more innovative applications of smart textiles in the future.

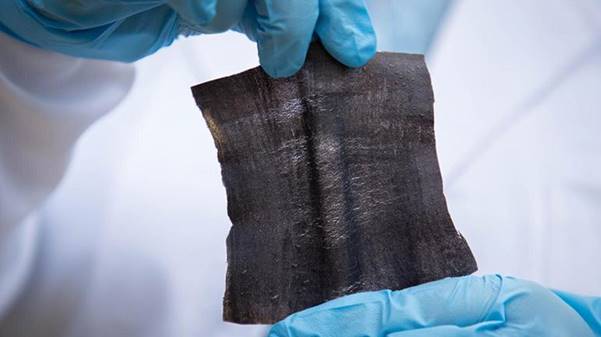

Sustainable Materials in the Textile Industry

The textile industry is one of the largest polluters in the world, with the production of textiles contributing to significant environmental damage. In recent years, there has been a growing demand for sustainable materials in the textile industry. Sustainable materials are those that have a reduced impact on the environment and are ethically sourced and produced.

Here are some examples of sustainable materials in the textile industry:

- Organic cotton: Organic cotton is grown without the use of harmful pesticides and fertilizers, reducing its impact on the environment. It also promotes ethical farming practices that prioritize worker safety and fair wages.

- Hemp: Hemp is a fast-growing crop that requires minimal water and pesticides to grow. It is a highly sustainable material that can be used to create durable and long-lasting textiles.

- Recycled polyester: Recycled polyester is made from recycled plastic bottles and other waste materials. It reduces the amount of waste in landfills and requires less energy to produce than traditional polyester.

- Tencel: Tencel is made from sustainably sourced wood pulp and is produced using a closed-loop manufacturing process that recycles water and solvents.

- Linen: Linen is made from the flax plant and requires less water and pesticides to grow than cotton. It is also highly durable and long-lasting, making it a sustainable alternative to cotton.

The use of sustainable materials in the textile industry has numerous benefits. It reduces the environmental impact of textile production, promotes ethical farming practices, and supports a more sustainable and equitable industry. As consumer demand for sustainable textiles continues to grow, we can expect to see more sustainable materials being used in the production of textiles in the future.

Wrapping Up

The integration of nanotechnology, smart textiles, and sustainable materials will lead to the development of a more sustainable, functional, and innovative textile industry. As consumers become more conscious of the environmental impact of their purchasing decisions, textile manufacturers must adapt to meet the demand for more sustainable and ethical products.

Why Choose Colourinn for Textile & Dyes Auxiliaries

Choose Colourinn Industries for all your textile chemical needs and experience the difference for yourself. With our commitment to quality, safety, and sustainability, we have established ourselves as the leading textile auxiliary chemicals manufacturer in the industry.

Our wide range of products, from eco-friendly dyes to chemical auxiliaries, will meet all your textile needs. But it’s not just our products that set us apart. Our dedication to excellent customer service means you can expect hassle-free ordering and contactless delivery, ensuring you receive your products quickly and safely. So why settle for anything less than the best?

Experience the ultimate in quality, reliability, and customer service when it comes to your textile chemical needs. Contact us today to learn more!

Frequently asked questions:

Q.1. What is the future of textile technology?

Ans: The future of textile technology is promising with advancements such as smart textiles, sustainable textiles, 3D printing, and more.

Q.2. What is the role of nanotechnology in sustainable textiles?

Ans: The role of nanotechnology in sustainable textiles is to enhance their properties, durability, and functionality while reducing their environmental impact. It is also used to create textiles that are water and stain-resistant, self-cleaning, and more durable.

Q.3. What are the benefits of nanotechnology materials?

Ans: Nanotechnology materials can be used to create self-cleaning surfaces, water, and stain-resistant coatings, and more efficient energy storage and conversion devices.