Disperse dyeing is a specialized process for adding color to synthetic fibers (polyester, nylon, acrylic). In this article, we will discuss the science behind disperse dyes, the step-by-step dyeing process, parameters influencing dyeing efficiency and challenges & innovations. Whether you are in textile manufacturing, fashion or just interested in synthetic dyeing this guide will give a good grounding in disperse dyeing and its importance in modern textile fabrication.

Understanding Disperse Dyes

Disperse dyes are a group of synthetic dyes that are specifically designed for dyeing the hydrophobic (“water-repellent”) synthetic fibres (polyester, nylon, acrylic). Disperse dyes are not soluble in water but remain a fine suspension or dispersion in the dye bath, unlike traditional dyes that dissolve in water. This helps them to penetrate the close molecular structure of synthetic fibres that resist dyeing by conventional means.

The very high temperature required for the binding of disperse dyes, usually between explains their success with regard to synthetic fibers. By this process, at high temperature, the dye molecules diffuse within the fiber, and are anchored there, to give bright, permanent colors. Disperse dyes find a particularly good application on polyester which is the most common synthetic fiber in the textile industry.

Also, Read our blog: The Use of Dispersing Agents in Textile Industries

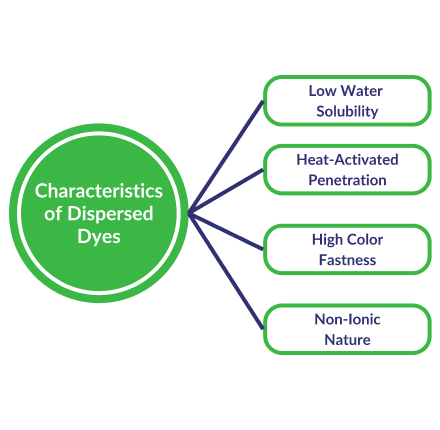

Key Properties of Disperse Dyes

- Low Water Solubility: Unlike reactive or direct dyes, dispersed dyes do not dissolve in water. They are instead suspended in a finely dispersed form for uniform dye application.

- Heat-Activated Penetration: The dispersed dyes need high temperatures (120°C–130°C) to allow dye molecules to enter synthetic fibers, so they are ideal for polyester.

- High Color Fastness: These dyes provide excellent resistance to washing, light exposure, and friction, ensuring vibrant and durable colours.

- Non-Ionic Nature: Unlike other dyes that rely on ionic bonding, these dyes interact with fibres through physical forces like van der Waals and hydrophobic interactions.

The molecular structure of dispersed dyes is designed to be small and non-polar, allowing them to diffuse into synthetic fibres effectively. Depending on their structure, disperse dyes are categorized into azo, anthraquinone, and triarylamine-based compounds, each offering a different shade range and stability. The majority of disperse dyes used today belong to the azo family, producing colours from bright yellows to deep reds.

The Disperse Dyeing Process

The disperse dyeing process ensures that synthetic fabrics absorb dyes uniformly with good color strength. Because hydrophobic polyester and other synthetics are hydrophobic, high temperatures and chemical dispersing agents are needed for dye uptake.

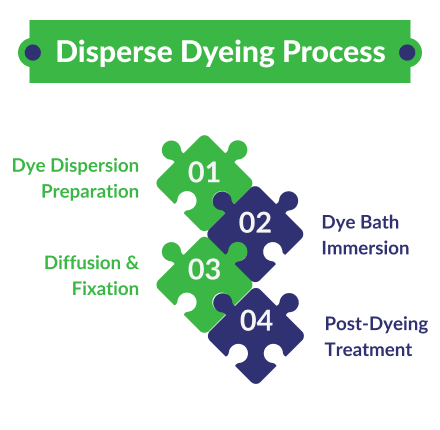

Step-by-Step Dyeing Process

- Dye Dispersion Preparation

Disperse dyes are ground to powder and combined with dispersing agents to form an aqueous Dispersion. This stops the dye particles from clumping together and ensures even color application. - Dye Bath Immersion

The synthetic fabric is soaked in a hot dye Bath, usually above 120°C, which softens The fiber structure and lets dye molecules penetrate. For temperature-sensitive fibers, chemical carriers are added to aid dye absorption at lower temperatures. - Diffusion and Fixation

The heat makes the polyester fibres expand and the dye molecules diffuse into The fibre structure. Like reactive dyes that chemically attach to fibres, dispersed dyes need physical interactions to stay put. - Post-Dyeing Treatment

Post-treatment, fabrics are rinsed to remove excess dye and chemicals After dyeing. Any dye not bonded properly may be removed by reduction clearing.

Key Factors Affecting Disperse Dyeing

- Temperature: The higher the temperature, the more effectively the dye penetrates polyester fibers. Industrial dyeing typically takes place at 120°C–130°C.

- Time: More prolonged dyeing times give better colour saturation but reduce fibre strength.

- pH Control: Maintaining a slightly acidic pH (4.5–5.5) ensures optimal dye performance.

- Dispersing Agents: These dispersing agents keep dye particles from clumping together ensuring uniform colouration.

Different dyeing methods are employed according to the fabric type and production requirements. Most common methods use high temperature dyeing, carrier dyeing and thermosol dyeing (dye is fixed at high temperature without water immersion). Each method has advantages like less water usage or deeper colour penetration.

Mechanism of Dye-Fiber Interaction

The effectiveness of disperse dyeing lies in the interaction between dye molecules and synthetic fibres. Unlike natural fibres, which bond chemically with dyes, synthetic fibres require a physical absorption process.

How Disperse Dyes Bind to Fibers

- Adsorption

Dye molecules initially attract the fiber surface via hydrophobic interactions. The absence of water-soluble groups in dispersed dyes makes them particularly attracted to non-polar polyester fibres. - Diffusion into the Fiber

Heat expands polyester fibres creating microvoids for the dye to enter. Lesser dye molecules diffuse faster than larger molecules affecting colour depth and shade consistency. - Retention and Fastness

Cooling the fiber retains and fastens the dye molecules inside, giving a strong wash and quickness. As the dispersed dyes do not bind covalently to the fiber, they must adhere to the fiber by van der Waals forces and hydrogen bonding.

Challenges in Dye-Fiber Interaction

- Uneven Dye Uptake: Poor dispersion causes patchy or streaky dyeing.

- Dye Aggregation: If dye particles may be clumped together If they are not dispersed properly, affecting shade uniformity.

- Environmental Concerns: Traditional dyeing processes use a lot of water and energy. Alternatives are being investigated such as supercritical CO2 dyeing.

Conclusion: Colourinn’s Commitment to Quality in Disperse Dyeing

At Colourinn Auxiliaries, we understand the intricacies of disperse dyeing and the demands of modern textile production. Our high-performance disperse dyes for polyester are developed for deep color penetration, good fastness & eco-friendly processing. We innovate our dyeing solutions to abide by changing industry standards.

Custom dyeing solutions, technical support and sustainability are part of our promise to our clients for the best results in polyester dyes and other synthetic fabric applications. Whatever your field – textile manufacturing, fashion, industrial dyeing – Colourinn is the partner for brilliant, lasting colors. For even more about our products and technical knowledge, get in touch with our experts today!

Frequently Asked Question(FAQs):

Q1. What are the advantages of disperse dyeing?

A. Disperse dyeing provides vibrant colors, high wash fastness, durability, and is suitable for industrial-scale dyeing of synthetic fabrics.

Q2. How does disperse dyeing work?

A. The process involves suspending dye particles in water, heating the fabric to allow dye penetration, and fixing the color through diffusion into the fiber structure.

Q3. What are the different methods of disperse dyeing?

A. Common methods include high-temperature dyeing, carrier dyeing, and thermosol dyeing, each offers different benefits based on the fabric and dyeing requirements.