Turkey red oil (TRO), alternatively called sulfated castor oil, is an important industrial chemical. It is a derivative of castor oil, an industry standard in the textiles and cosmetics industries. In this article, we will explore turkey red oil in detail—what makes it special, how it’s produced, and why it plays a key role in many industries.

Turkey Red Oil Explained

Turkey Red Oil is a pale yellow viscous liquid obtained by a chemical process. It mostly consists of sulfonated ricinoleic acid, derived from castor oil. This unique modification makes turkey red oil a valuable component in many applications.

An important characteristic is that TRO is a strong wetting agent It decreases the surface tension of water so it penetrates and spreads on fabrics. This helps dyes distribute evenly and increases color absorption.

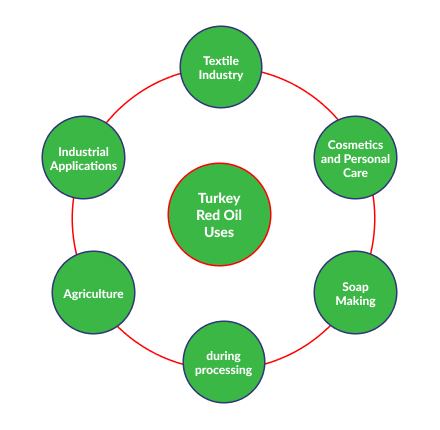

Turkey Red Oil Uses

Because of its unique and rich properties, TRO is a versatile compound used in many different industries.

- Textile Industry: TRO acts as a wetting agent and dyeing assistant, allowing dye penetration and uniform colouration of fabrics. Its emulsifying properties allow the even distribution of dyes, resulting in uniform colors.

- Cosmetics and Personal Care: In bath oils, shampoos, and lotions, TRO emulsifies so that the oil and water components blend together easily. So you get stable, homogeneous products with a mild texture to the skin.

- Soap Making: TRO is a superfatting agent used to make transparent soaps. It is water soluble so it mixes well into soap formulations.

- Agriculture: In agriculture, TRO is applied as an organic manure to promote plant growth. The emulsifying action also makes it useful for pesticide formulations—for uniform application on crops.

- Industrial Applications: TRO is used as a defoaming agent in the sugar and paper industries to control foam during processing. It also lubricates metalworking fluids and disperses in rubber compounding.

Learn about the Role of Enzymes in the Textile Industry in our article enzymes’ Role in the textile industry. This piece shows how enzymes – especially desizing – can change fabrics for dyeing or finishing.

Turkey Red Castor Oil Benefits

- Water Solubility: Unlike regular castor oil, TRO is completely soluble in water and thus a good emulsifier for formulations requiring an even distribution of oil and water components.

- Emulsifying Properties: It emulsifies oils to give better stability and texture to cosmetic and personal care products.

- Mild on Skin: Since it originates from nature, it doesn’t irritate the skin and is thus used in personal care items.

- Moisturizing Abilities: TRO retains the moisturizing effect of castor oil and is a natural humectant—a moisture retainer—on hair and skin.

- Biodegradability: Like all synthetic surfactants, TRO is produced from natural castor oil, making it biodegradable in many formulations.

Manufacturing Process of Turkey Red Oil

Step #1 Extraction of Castor Oil

The manufacturing process begins with castor oil obtained from the seeds of the castor plant Ricinus communis. The seeds are cleaned and pressed to express the oil that is filtered to remove other material. High-quality castor oil is the basis of turkey red oil and is critical for a quality end product.

Step #2 Sulfonation Reaction

In this crucial step, the castor oil is sulfonated. This means adding concentrated sulfuric acid or sulfating agents to the oil. The acid combines with the hydroxyl group in the ricinoleic acid of castor oil to give sulfonic acid esters.

This chemical modification makes the oil water-soluble and suitable for applications requiring emulsification. The reaction is monitored as the amount of sulfuric acid added must be controlled lest the oil be degraded and the efficacy diminished.

Step #3 Neutralization

The mixture is neutralized by an alkaline agent like NaOH after the sulfonation reaction. This helps stabilize the product and remove any residual acidity that may affect TRO safety and performance. The neutralization guarantees that the final product can be used safely in industries as well as in quality standards.

Step #4 Washing and Purification

The neutralized mixture is washed several times to remove remaining acids, byproducts, or impurities. In this phase, water or brine solutions are usually added to purify. Purification is essential to get a clear TRO of good quality because any residual by-products influence the application performance.

Step #5 Filtration

The last step is filtering the oil to the desired clarity and consistency. This step removes any particulates and other residual stuff, leaving behind something that is pure and water-soluble. During manufacturing, quality control measures are in place.

That includes testing for pH, purity, and water solubility to ensure TRO meets industry standards and application requirements.

Read How to Make Turkey Red Oil: The Complete Guide to Turkey Red Oil Production & Use. This article explores the properties that make TRO a staple in the textile and personal care industries.

How to Choose the Right Turkey Red Oil Supplier

A reputable turkey red oil supplier is important when sourcing TRO. The reliable suppliers will supply industry-standard TRO that is free of contaminants. Choose a supplier:

- Certifications: Find out if the supplier meets quality and safety standards like ISO certifications.

- Product Consistency: Find suppliers that offer consistent product quality.

- Sustainability: Choose suppliers that use sustainable methods to produce castor oil and some derivatives.

Conclusion: Why Colourinn is Your Go-To Supplier

As a leading Turkey Red Oil Supplier, Colourinn continues to provide sustainable and high-quality solutions to its esteemed clients across a range of industries.

We produce dyes and textile auxiliaries of the highest quality. Our deep knowledge of turkey red oil production and commitment to sustainable practices sets us apart in the industry.

Want to discover how turkey red oil can benefit your products? Get in touch with us for more details on our customized services & expertise.

Frequently Asked Questions

Q1. Which material is best for cold storage?

A. The insulation materials utilized by cold storage are as follows: Polyurethane (PIR) This material is mostly applied as an insulation material which has remarkable insulating properties and mechanical strength, so that it avoids heat transfer and minimizes the loss of heat.

Q2. How is Turkey’s Red Oil produced?

A. Turkey Red Oil is produced by a process called sulfonation, where castor oil reacts with sulfuric acid or a mixture of sulfur trioxide and water. This process forms a sulfonate group that gives the oil its emulsifying properties.

Q3. How should Turkey’s Red Oil be stored?

A. Turkey Red Oil should be stored in a cool, dry place, away from direct sunlight and heat sources. It should be kept in tightly sealed containers to prevent contamination and preserve its effectiveness.