Dyeing textiles meets design, performance and sustainability standards whether for fashion, home textiles or industrial fabrics. With textile production, dyeing techniques have evolved to provide solutions for color fastness, efficiency and environment friendliness. From historic natural dyes to synthetic dyes today the industry is always evolving to meet both aesthetics and sustainability goals. Understanding dyeing methods and dyeing auxiliaries is very important for textile production with minimum environmental impact.

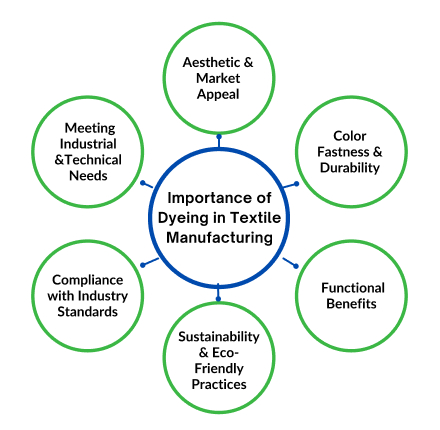

Importance of Dyeing in Textile Manufacturing

Dyeing is among the most critical steps in textile manufacturing – it affects the look, function and commercial value of fabrics. New developments in dyeing technology enable manufacturers to use less water, increase dye absorption and minimize chemical waste.

1. Aesthetic and Market Appeal:

A fabric’s color is what consumers see first and is therefore a deciding factor when they buy. Well-dyed textiles draw attention and increase product desirability – in fashion, home furnishings or industrial applications. Dyeing also lets manufacturers customize colors, patterns and finishes. Good dyeing methods achieve the uniformity required for premium textile production.

2. Color Fastness and Durability:

Textiles experience washing, drying and exposure during their lifecycle. A poorly dyed fabric will quickly fade, lose its appeal and have less value. Advanced dyeing techniques guarantee high colour fastness – the fabric does not yellow with sunlight, detergents or wear. This durability is improved by dyeing auxiliaries.

3. Functional Benefits:

Some dyeing methods perform functions beyond aesthetics. Special dyes make textiles UV-resistant, antibacterial or even water-repellent. Such innovation is particularly applicable to sportswear, medical textiles & military gear applications where fabric performance is just as important as appearance.

4. Sustainability and Eco-Friendly Practices:

Increasing environmental concerns lead the textile industry to sustainable dyeing solutions. Traditional dyeing uses up too much water and chemicals. Yet even today, low-water dyeing technologies, bio-based dyes and digital printing have reduced the environmental impact. Now some textile manufacturers concentrate on textile dyeing auxiliaries that optimize color application with minimum waste.

5. Compliance with Industry Standards:

Textile industry regulations ensure fabric safety and quality. The dye process helps meet international Textile standards such as OEKO-TEX and GOTS (Global Organic Textile Standard). Such certificates ensure that the dyes and processes used are safe for humans and the environment.

6. Meeting Industrial and Technical Needs:

A dye manufacturer has a role beyond fashion, serving various industrial sectors. Automotive textiles and upholstery, medical fabrics and industrial workwear need to be dyed precisely, to meet requirements such as that of flame resistance, chemical resistance or very high durability for long-term uses.

Also read our blog on What is the role of leveling and wetting agents in the textile dyeing industry?

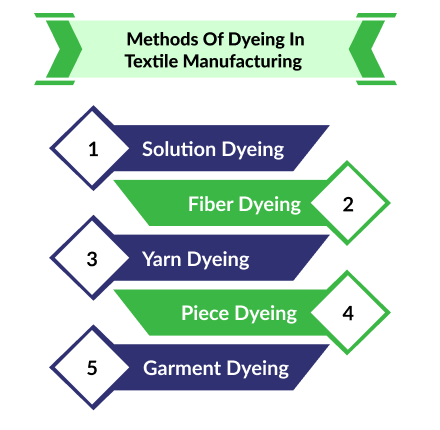

Methods of Dyeing in Textile Manufacturing

The dyeing process in textile manufacturing can be executed at various stages, each method offering unique advantages and suited to specific requirements:

1. Solution Dyeing:

This involves integrating pigments directly into the polymer solution before fiber extrusion – also called dope dyeing. Mostly used for synthetic fibers, solution dyeing is colorfast and economical for mass production. It has limited color options and requires early color decisions.

2. Fiber Dyeing:

This involves dyeing fibres before they are spun into yarns to achieve deep colour penetration and uniformity. Fibre dyeing is best for heathered or mottled effects in fabrics. It is more expensive however and requires early color decisions during manufacturing.

3. Yarn Dyeing:

In yarn dyeing, yarns are dyed before weaving or knitting to produce stripes, checks and plaids. Such a method assures uniform colour distribution and is suitable for fabrics with multiple colours. For gingham and denim fabrics yarn dyeing is used.

4. Piece Dyeing:

Piece dyeing is also known as fabric dyeing and involves dyeing the fabric once it has been woven or knitted. Such a method is economical and allows a fast reaction to fashion trends since colour decisions are made later in the production process. However uniform dye penetration in thicker fabrics is difficult.

5. Garment Dyeing:

This involves dyeing the finished garment, giving freedom of color choice and the ability to satisfy immediate market demands. Garment dyeing is best for casual wear and for garments that do not need exact color matching of components. It may not be suitable for garments made of more than one fabric type or trims which react differently with dyes.

The Role of Auxiliaries in Achieving Superior Dyeing Results

Dyeing auxiliaries affect the efficiency and quality of the dyeing process. Such chemicals help with various aspects of dyeing – achieving optimal results – and overcoming difficulties inherent to the process.

- Wetting Agents: Wetting agents reduce the surface tension of water so the dye solution penetrates more uniformly into the fabric. This gives consistent color and avoids uneven dyeing or streaks.

- Leveling Agents: The leveling agents disperse the dye molecules evenly throughout the textile material, avoiding localized concentrations that cause color inconsistencies. They’re especially important when dyeing synthetic fibers which may have different affinity for dyes.

- Sequestering Agents: Sequestering agents bind with metal ions in the dye bath which might otherwise be complex with the metal in the dye. Neutralizing these impurities helps to sequester agents and maintain the stability and efficacy of the dye solution.

- Fixing Agents: Fixing agents bind dye molecules to fibers resulting in better color fastness, resistance to washing and low light exposure. They are also required for reactive and many direct dyes on cellulose fibers (cotton).

- pH Regulators: Maintaining the correct pH during dyeing is important to achieve color and dye uptake; pH regulators adjust the acidity/alkalinity of the dye bath to suitable levels for particular dye-fiber combinations.

Conclusion: Colourinn’s Commitment to Excellence in Dyeing

At Colourinn Auxiliaries, we are aware of the importance dyeing has in textile manufacturing. Commitment to quality & innovation leads us to offer textile dyeing auxiliaries of the utmost quality as well as to co-work closely with manufacturers to obtain brilliant, fast & ecological results. Integrating advanced technologies and eco-friendly practices we are moving the industry towards a more colourful and sustainable future.

For businesses looking to achieve vibrant, durable, and sustainable textile dyeing, Colourinn, the leading dyes manufacturer is your trusted partner. Explore our dyeing solutions & start producing textiles today!

Frequently asked Question(FAQs)

Q1. Why is dyeing important in textile production?

A. Dyeing improves the aesthetic value of fabrics, enhances durability, provides functional benefits (e.g., UV resistance, antibacterial properties), and ensures compliance with industry standards.

Q2. What are the most common types of dyes used in textile dyeing?

A. Common types include reactive dyes (for cotton), disperse dyes (for polyester), acid dyes (for wool & silk), and vat dyes (for durability and brightness).

Q3. What is the difference between dyeing and printing in textiles?

A. Fabric dyeing means applying a uniform color to an entire textile, While printing applies patterns or designs on the surface of the fabric through the use of dyes and pigments.